Manage water recycling

Control microbiological growth associated with water recycling

Ensure production continuity

Limit the formation of slime (biofilm) leading to paper breaks, stains, discoloration…

Reduce environmental impact

Master the use of treatment products and limit highly polluted wastewater (filamentous bacteria, biocide, bio dispensant…)

Industrial laundry

RABC approach

Proactively address microbiological deviations that may result in regulatory non-compliance

Save

Optimize the dosage of laundry products, washing temperatures, load ratios…

Reduce environmental impact

Decrease water consumption and limit the release of harmful agents into the environment (AOX, phosphorus, detergents…)

Electroplating

Reduce defects on treated parts

Control the absence of biofilm and bacteria in the plating and rinsing baths

Ensure production continuity

Trigger cleaning and disinfection operations for baths only when necessary

Save

Avoid unnecessary production shutdowns, costs of non-quality, recalls, or batch rejections…

WHAT IS DENDRIDIAG®  ?

?

It is a complete FIELD KIT designed to RELIABLY and INSTANTANEOUSLY measure the quantity of BACTERIA in process water.

The ATP test kit was conceived to meet your needs: ease of use, speed, reliability… serving as both a decision support and diagnostic tool.

High quality reagents, all made in France.

A 2 minutes analysis!

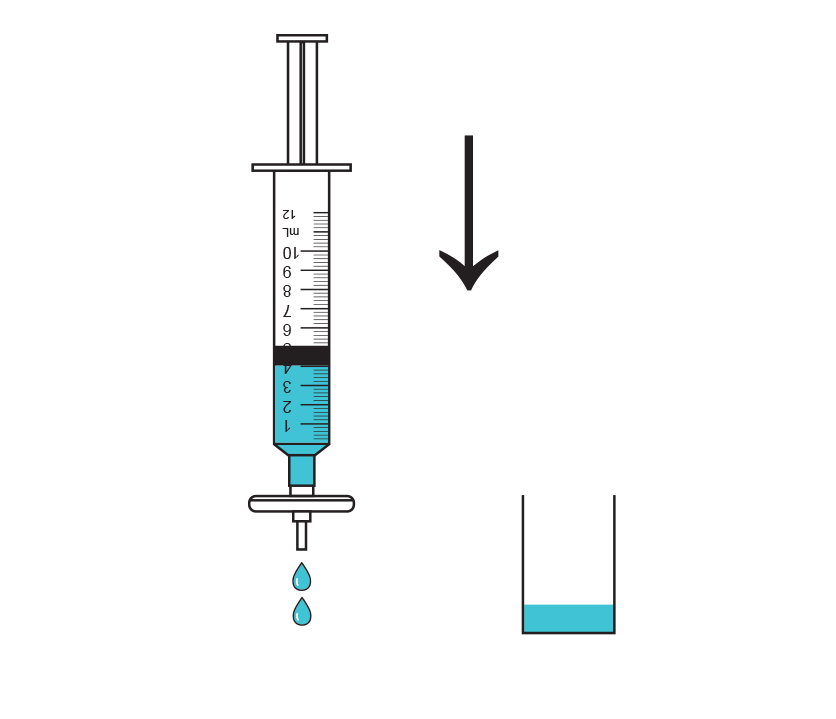

1. Filter the sample

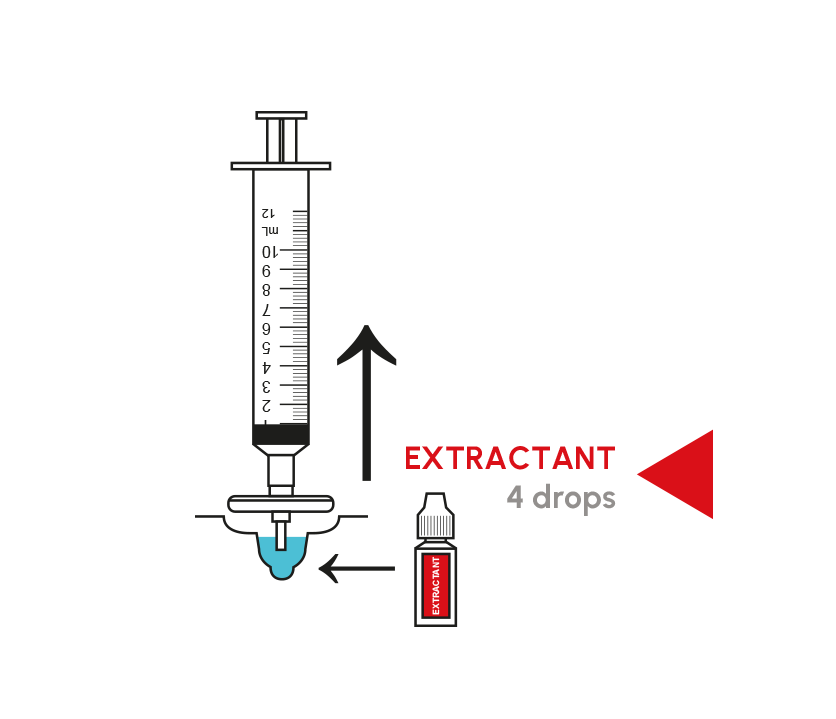

2. Extract the ATP

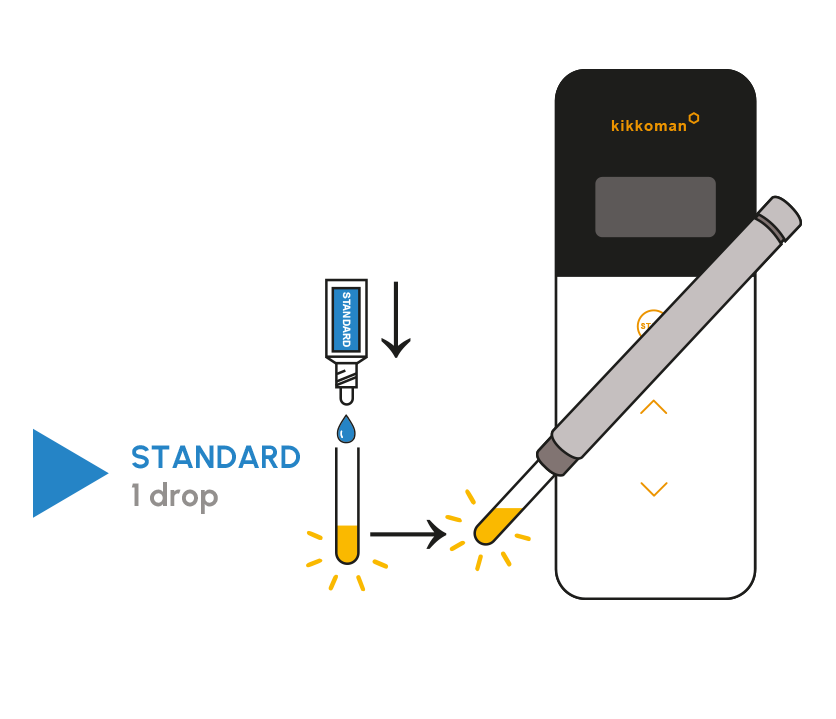

3. Quantify the ATP

4. Validate the analysis

A reliable analysis

- Reprensentative sampling

- Low detection limit

- Elimination of free ATP and inhibitors

Extraction of bacterial ATP

- Analysis of the whole sample

- No dilution

- High sensitivity

- No time wasting

Measure in 10 seconds

- Instantaneous analysis of your sample

- Only intracellular ATP is measured

Test validation

- Quantitative results

- Consideration of environmental parameters

- Avoid false negatives

Get the result in a second

The app helps you interpret the results to react immediately in case of microbiological deviation.

Set up

Presentation and on-line demo

Identification of needs

Shipment of products

Scheduling of the training date

1 week

01

Rollout

On-site or remote training

Identification of sampling points

1 month

02

Personalized support

Result analysis

Reassessment of the sampling points

Validation of the thresholds

1 year

(Continuous monitoring with ATP tests…)

03

Quality control

Verification of the device

Customer feedback

04

Learn more

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•

They trust us • They trust us • They trust us•